Refueling in 3 minutes compared to 30 minutes.

Toyota and BMW Double Down on Hydrogen Fuel Cell Engine Technology

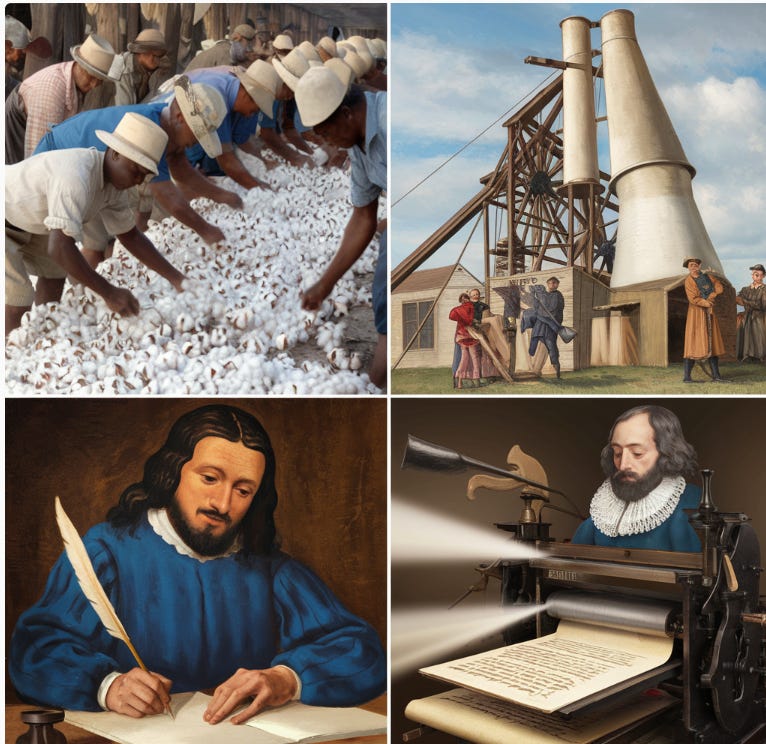

The cotton gin revolutionized cotton processing, making it 50 times faster than manual seed removal. Movable type printing dramatically increased book production speed, with a skilled printer able to produce around 3,600 pages per workday, compared to a scribe's output of only a few pages per day by hand. These innovations significantly accelerated their respective industries.

Projections based on existing technologies often fail to account for unforeseen innovations and discoveries. During the Industrial Revolution, extrapolating coal consumption in major cities like London, Berlin, Hamburg, New York, Chicago, Pittsburgh or Cleveland might have suggested an impending energy crisis.

However, such predictions would have overlooked the subsequent discovery of oil in Pittsburgh, the emergence of natural gas, and the development of electricity and nuclear power.

These advancements ultimately alleviated the pressure on coal resources, demonstrating the limitations of linear forecasting in a world of rapid technological change.

I remember one special hot Pittsburgh July evening (in the summer after 5th grade.)

The air was thick with the smell of sulfur and asphalt pavement and the city streets were bustling with piercing sounds of horns honking and rush hour traffic echoed in the distance as we took the train to downtown to meet my dad, who was finishing up his business day.

We would start our journey at my dad's Westinghouse office (near where the three rivers meet) then walk across the bridge over the Allegheny River to check out a Pirates baseball game.

Once, I remember my dad pointing to all the overhead wires and telling me that his boardroom had contingency plans for a massive copper shortage. The telecommunications industry was blowing up internationally with transcontinental wiring systems using millions of pounds of copper.

But then, seemingly out of nowhere a new discovery emerges - Welcome to our World Mr. Fiber optics

The development of fiber optics significantly reduced pressure on the global copper market. The transition from copper to fiber is ongoing, with significant growth expected in the coming years. For instance, in the U.S., 137 million homes are expected to have fiber broadband by 2028

So, as we’ve discussed on this channel dozens of times, transitions such as:

Wood burning to coal-fired

coal to oil

oil to natural gas

advent of electricity

advent of nuclear

Each new energy source doesn’t knock out the previous, but they are used together.

And this explains why the Green Energy Cult is mostly a scam

We’re going to need all the Energy

it isn’t this or that, it’s this and that

Silver is a much more affordable catalyst in Hydrogen fuel cell cars, vans, busses, ships & ferries than compared to platinum group metals

right when we are led to believe that the next Energy crisis will hit, voila, a new fuel emerges. Hydrogen fuel cells cars, buses, vans, ships, barges, ferries could use more Silver than Solar … anything’s possible.

Toyota’s 3rd Generation Fuel Cell System Redefines Efficiency

Toyota has officially unveiled its 3rd Generation Fuel Cell System, introducing significant advancements in hydrogen technology for both commercial and passenger applications. This latest iteration promises remarkable durability, efficiency, and cost-effectiveness improvements compared to its predecessor. Explicitly designed to rival the robustness of traditional diesel engines, the system offers a tangible step forward in making hydrogen a practical and viable option for mass-market use.

Scheduled for deployment in markets like Japan, Europe, North America, and China by 2026, the 3rd Gen system is not limited to cars. It’s being targeted for heavy-duty commercial vehicles like trucks and buses, industries where hydrogen-powered solutions may shine due to their quick refueling times and potential for high mileage. The centerpiece of the technology is a smaller, more compact design that achieves 20% greater efficiency while slashing costs, a key hurdle for hydrogen adoption.

With increased hydrogen fuel station infrastructure—partly driven by freight and transportation sector needs—Toyota aims to make hydrogen-powered vehicles not just an experiment but a practical reality.

Key Features of Toyota’s 3rd Generation Fuel Cell System

Enhanced Durability

The 3rd Generation Fuel Cell System is built to last, with twice the durability of the previous version. This upgrade puts it on par with diesel engines' reliability while introducing a maintenance-free design for smoother, long-term operation.

Boosted Fuel Efficiency

Another highlight is greater efficiency. Compared to earlier models, it offers 20% more cruising range, making it more effective and practical for everyday drivers and commercial operations.

Reduced Production Costs

Toyota has achieved significant cost savings by streamlining the cell design and manufacturing processes. This makes the technology more accessible while maintaining top-tier performance.

Wide Adaptability

Designed for versatility, the system is suitable for a variety of uses. The technology can seamlessly integrate across multiple industries, from passenger vehicles to heavy-duty trucks, ships, rail systems, and stationary generators.

Compact and Flexible Design

A more compact build ensures the system fits easily into different types of vehicles, making it practical for widespread adoption, especially in commercial sectors requiring high power and endurance.

Improved Performance for Passenger and Commercial Vehicles

The added efficiency means extended range and greater peace of mind on the road for passenger cars. On the commercial side, the system delivers high power and durability comparable to diesel engines, ideal for trucks and buses tackling heavy-duty workloads.

Toyota’s 3rd-Generation Fuel Cell System represents a significant step toward a hydrogen-powered future, combining innovation with real-world practicality.

BMW’s Hydrogen Journey Reaches a New Milestone

While Toyota’s advancements underscore its engineering prowess, BMW’s hydrogen mobility progress is worth noting.

The German automaker has been exploring hydrogen technology for over four decades, beginning in 1979 with its modified hydrogen-powered 520h. BMW’s approach has evolved considerably since then, and it recently announced plans for its first mass-production hydrogen vehicle, which is expected to launch in 2028.

The upcoming BMW iX5 Hydrogen, based on the next-gen X5 platform (codename G65), is a critical step in BMW’s hydrogen road map. This vehicle integrates a Toyota-supplied fuel cell and BMW’s proprietary powertrain system, boasting a range of 313 miles per refilling and delivering 400 horsepower.

After extensive global field tests covering over one million kilometers, BMW is confident its hydrogen SUVs can meet drivers’ expectations for reliability and performance.

BMW’s drive portfolio will soon include five options—electric, plug-in hybrid, diesel, petrol, and hydrogen. This multi-strategy approach reflects the brand’s belief in technological openness and the potential of hydrogen as a seamless extension of its growing electric lineup.

Why Hydrogen Matters Despite the Skepticism

Hydrogen mobility, despite its underdeveloped infrastructure and energy-intensive production methods, holds significant potential for reducing carbon emissions.

Advancements like green hydrogen, produced via electrolysis using renewable electricity, are addressing some of these concerns.

Companies like BMW and Toyota are banking on a domino effect—heavy industries such as shipping and freight are beginning to adopt hydrogen on a larger scale, which could lead to the expansion of refueling networks for everyday drivers.

Hydrogen vehicles also excel in areas where battery-electric technology struggles. Long charging times and diminished range in colder climates are key limitations of battery-electric vehicles (BEVs).

Hydrogen, in contrast, mimics the usage patterns of traditional combustion engines; refueling takes just 3-5 minutes, offering a practical alternative for users who need convenience and speed.

Additionally, regions with renewable energy surpluses—such as wind power from offshore farms—can use that excess energy to produce green hydrogen, further integrating this technology into sustainable power grids.

How Toyota and BMW Could Reshape Transportation

Together, Toyota and BMW are demonstrating that hydrogen isn’t merely an alternative; it’s a complement to electrification, addressing use cases where battery-powered systems fall short. For Toyota, logistics and heavy-duty transport applications could catalyze hydrogen’s growth. Similarly, BMW’s hydrogen SUVs provide an option for premium customers desiring sustainability without compromising on performance. Their leadership in this area is inspiring and could reshape the future of transportation.

The significance, however, extends beyond the automotive industry. Hydrogen-powered forklifts, long-haul trucks, and even trains and ships already show that zero-emission solutions aren’t confined to city buses or niche projects. If costs continue to decline and infrastructure develops, hydrogen could emerge as a major player in achieving decarbonization goals across sectors, offering a promising future.

Looking forward, hydrogen technology could play a crucial role in the broader energy transition as electric vehicle adoption surges.

By offering an alternative energy carrier, hydrogen may help balance demand and diversify the energy mix.