Just like email replaced Fax and Mobile Phones replaced Pagers: Silver Solid State Battery will replace traditional EV Battery.

Silver EV Battery will devour nearly three times the current global annual Silver production.

Facts:

World annual Silver production is at 803,768,664 troy ounces.

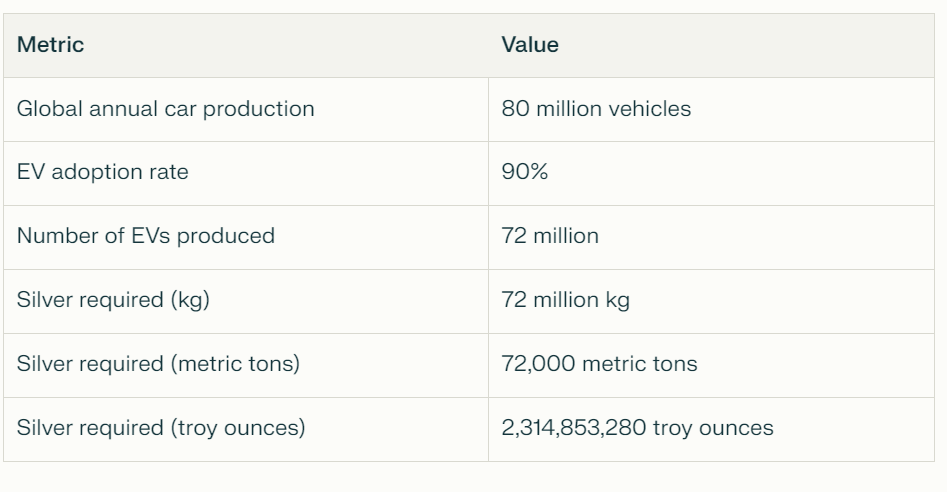

Global annual car production: approximately 80 million vehicles

90% adoption rate: 72 million EVs

Silver required: 72 million kg (72,000 metric tons)

Converting to troy ounces:

1 kg = 32.15074 troy ounces

72 million kg × 32.15074 =

2,314,853,280 troy ounces of silver

This represents about 3 years of World Total Silver Mining

Meanwhile Mexico is moving closer to Nationalizing Silver

If you ask why would there be 90% adoption then this article is for you

Jeff Christian will now launch a video that says people love batteries that expire quicker and would prefer batteries with short range and take double the time to charge.

Throughout history, superior innovations have consistently replaced their predecessors, revolutionizing industries and improving our daily lives. The emergence of a better solution often renders existing technologies obsolete, as seen when the flashlight supplanted kerosene lanterns. This pattern of technological evolution is evident across various sectors:

The typewriter gave way to the word processor and computer. Paper maps were superseded by GPS navigation systems. Fax machines were rendered obsolete by email and digital document sharing. The abacus was replaced by mechanical and digital calculators. Pagers were made redundant by cell phones and smartphones

These examples illustrate how innovation drives progress, with each new technology offering improved efficiency, convenience, or functionality. The same principle applies to Samsung's solid-state battery technology for electric vehicles, which promises to revolutionize the industry with its superior performance characteristics.

Samsung's new solid-state battery technology for electric vehicles (EVs) offers significant improvements over current lithium-ion batteries.

The potential impact on silver demand:

Key Battery Attributes

Range: 600 miles (nearly double the average range of current EVs)

Lifespan: 20 years (considerably longer than lithium-ion)

Charging time: 9 minutes (significantly faster than current EVs)

Energy density: 500 Wh/kg (about twice as dense as current EV batteries)

Silver Demand

While the exact silver content per battery is not officially confirmed, estimates suggest:

Up to 5 grams of silver per battery cell (conservative estimate when considering we have not begun doing all the calculations for trucks, vans, buses)

Approximately 1 kg of silver per vehicle for a 100 kWh capacity battery pack

Calculation of Silver Demand

Given the superior performance characteristics, let's assume a 90% adoption rate of this technology for new EVs:

Global annual car production: approximately 80 million vehicles

90% adoption rate: 72 million EVs

Silver required: 72 million kg (72,000 metric tons)

Converting to troy ounces:

1 kg = 32.15074 troy ounces

72 million kg × 32.15074 = 2,314,853,280 troy ounces of silver

This potential demand would far exceed the current global silver production, which is approximately 25,000 metric tons annually.

This converts to approximately World annual Silver production at 803,768,664 troy ounces.

The projected demand of 72,000 metric tons would be nearly three times the current annual production.

Market Implications

The significant increase in demand could drive silver prices substantially higher, reaching $200/oz in the next 2 to 10 years according to some analysts. The silver mining industry would need to dramatically increase production to meet this demand. The increased silver demand could have far-reaching effects on various industries that rely on silver, potentially leading to price increases in other sectors.

-- Toyota Motor and Subaru will launch a jointly developed electric vehicle in Japan, the U.S, and Europe in 2026,

Production will begin around January 2026 at Subaru's Yajima plant, in Japan's Gunma prefecture, with production capacity rising to between 15,000 and 20,000 vehicles per month.

With EV prices remaining high, the partners aim to reduce production costs and shorten development time by standardizing key components.

Toyota and Subaru jointly developed an electric sport utility vehicle in May 2022 and launched it as the Toyota bZ4X and the Subaru Solterra.

The new EV will also be a SUV incorporating parts from the bZ4X and other models to keep costs down. It is expected to be sold mainly in North America, Europe and Japan.

Subaru had announced at a May 2024 news conference that it and Toyota would mutually supply four EV models by the end of 2026. Having determined that it would be difficult to develop EVs on its own, the automaker will strengthen its lineup with the help of Toyota.

By 2030, Subaru aims to sell 600,000 EVs per year, with electric vehicles making up 50% of its global sales.

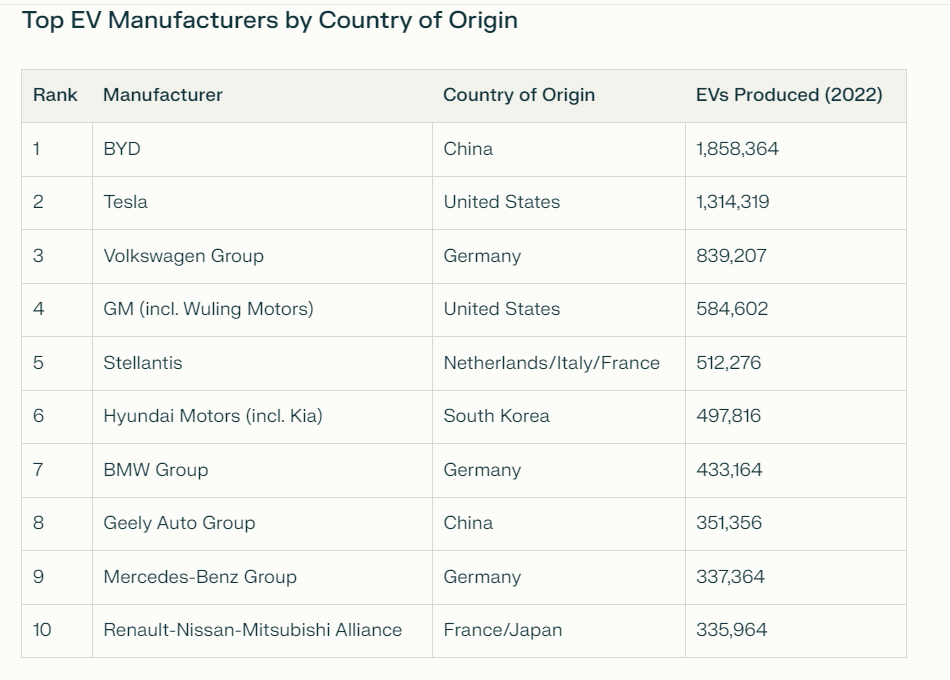

Now stare at this 600,000 number and look at the Silver use chart above then understand that Subaru, Honda and Toyota are not even listed in top 10

Citations

https://asia.nikkei.com/Business/Automobiles/Toyota-and-Subaru-to-jointly-develop-EV-for-2026-launch?

https://www.jpost.com/business-and-innovation/precious-metals/article-816695

https://thesilverindustry.substack.com/p/samsungs-silver-solid-state-battery

https://thesilverindustry.substack.com/p/exploring-samsungs-silver-solid-state

https://www.reddit.com/r/Silverbugs/comments/1ewbzmv/silver_set_to_soar_on_samsungs_solidstate_battery/

https://thesilverindustry.substack.com/p/samsungs-silver-solid-state-battery/comments

https://thesilverindustry.substack.com/p/revolutionizing-transportation-the

https://thesilverindustry.substack.com/p/government-policies-driving-unprecedented